Modified Bitumen

Modified Bitumen

SBS Roofing Systems

What are asphalt roofing solutions and why are they trusted roofing solutions?

Asphalt is one of the oldest roofing technologies still in use today and it is a reliable solution for both residential and commercial roofing needs. Asphalt roofing uses asphalt as a waterproofing membrane.

Commercial asphalt roofing systems consist of two or more waterproofing layers. This redundancy provides building owners with durable waterproofing protection.

Asphaltic Roofing Systems

Multi-ply construction gives peace of mind that the roof is durable

BUR (Built-Up Roofing)

BUR is the oldest of the current roofing technology and has been around for over a century. It consists of melting bricks of hot asphalt in a large metal kettle and using mops to apply that asphalt in-between a base sheet, ply sheets and lastly a cap sheet. Ply sheets and additional layers of asphalt can be added until the desired thickness has been reached. While cap sheets are very popular, they are not used on all jobs. Instead of using a cap sheet, some jobs are finished with a layer of gravel spread out over the last layer of asphalt.

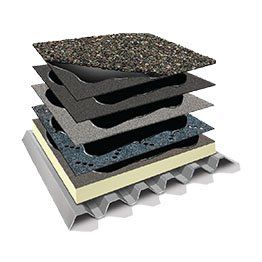

SBS (Styrene Butadiene Styrene)

Introduced in the 1970’s, SBS features asphalt that has been modified (thus called modified bitumen) with the polymeric material SBS. This synthetic rubber allows the SBS sheets to achieve greater elongation ratings than other asphaltic systems. SBS systems also have the widest range of application methods as they can be hot-mopped, cold-applied, heat-welded or self-adhered. A typical SBS system consists of two plies of roofing membrane. First, a ply of smooth-surfaced SBS base sheet is installed, usually over insulation or cover board. The system is finished with a granulated cap sheet applied over the smooth base/ply sheet. SBS membranes are classified by ASTM numbers, types and grades:

- ASTM D6162: SBS sheet using a combination of both polyester and glass fiber

- ASTM D6163: SBS sheet using glass fiber reinforcement

- ASTM D6164: SBS sheet using polyester reinforcement

ASTM D6162 and D6163 have three type classifications, Type I, Type II and Type III.

ASTM D6164 has two type classifications, Type 1 and Type 2. Typically, the higher the type, the larger the mass and physical properties. There are two grades of SBS sheet:

- Grade S: The sheet has a smooth surface

- Grade G: The sheet has a granule surface

ASTM number, type and grade are specified by the architect in most cases.

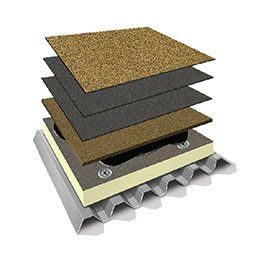

APP (Atactic Polypropylene)

Introduced first in Italy in 1965 and subsequently brought to the United States one decade later in 1975, APP features asphalt that has been modified (thus called modified bitumen) to include atactic polypropylene – a plastic that allows the roofing membrane to achieve durability in addition to protection against the damaging effects of UV rays and weather events.. APP is typically only applied via a torch – a key difference from SBS. Just like SBS systems, most APP systems will consist of two membranes, a smooth sheet and a granule cap sheet. However, APP sheets are typically installed over either a BUR base sheet or thermal barriers as many substrates cannot be directly torched to. APP sheets are also used to recover existing roof systems. APP membranes are classified by ASTM numbers, types and grades.

- ASTM D6222 – APP sheet using polyester reinforcement

- ASTM D6223 – APP sheet using a combination of both polyester and glass fiber reinforcement

ASTM D6222 and D6223 have two type classifications, Type I and Type II. Typically Type II will have a larger mass and higher physical properties than Type II. There are two grades of APP sheet:

- Grade S: the sheet has a smooth surface

- Grade G: the sheet has a granule surface

ASTM number, type and grade are specified by the architect in most cases.

EnergyCap™

Although not a separate type of roof technology like BUR, SBS or APP, energy cap roofing membranes are factory coated white cap sheets that reflect sunlight away from the roof and meet ENERGY STAR guidelines.There is an EnergyCap™ cap sheet available for each of the roofing technologies mentioned above.